Puller guide

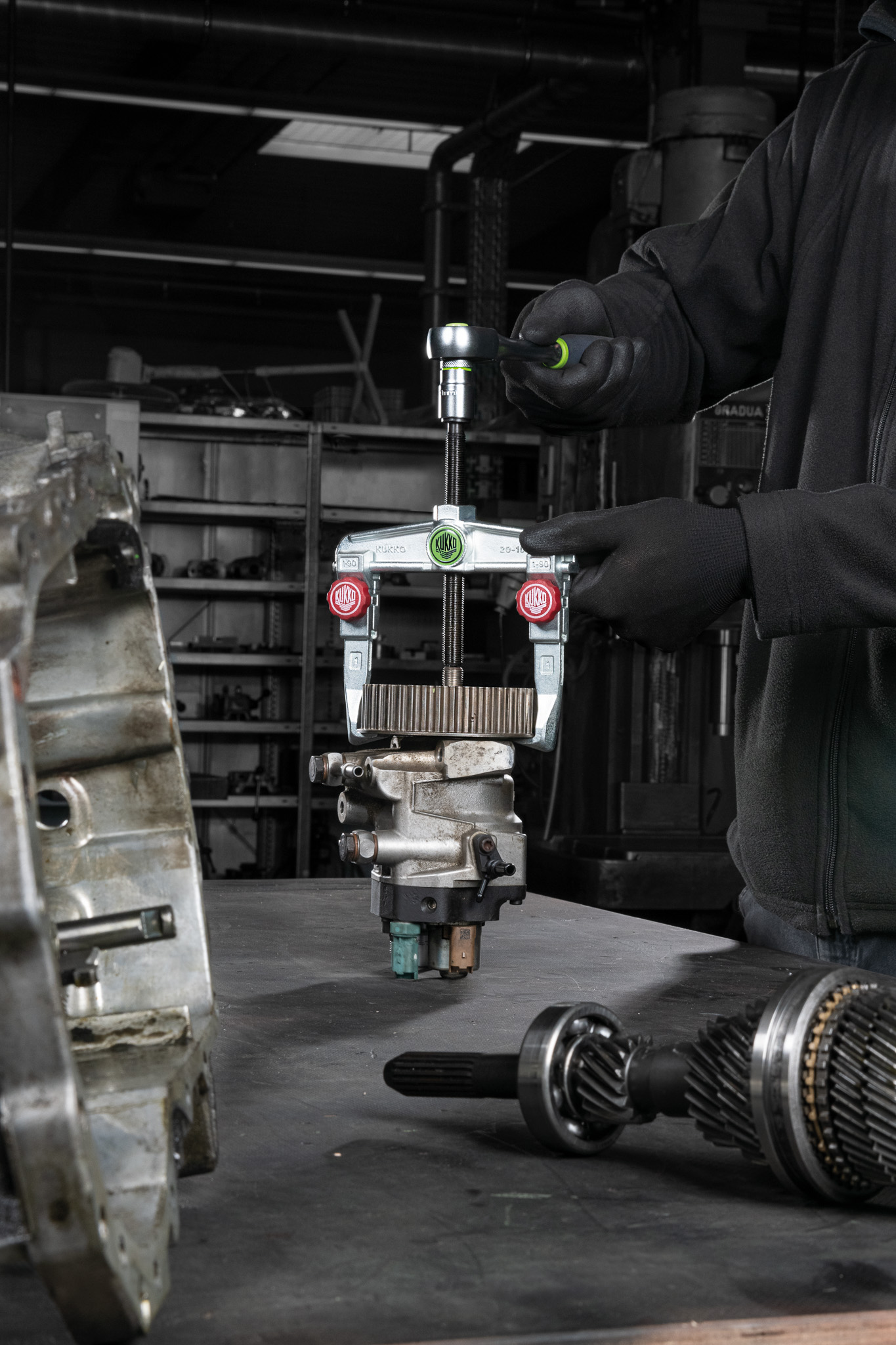

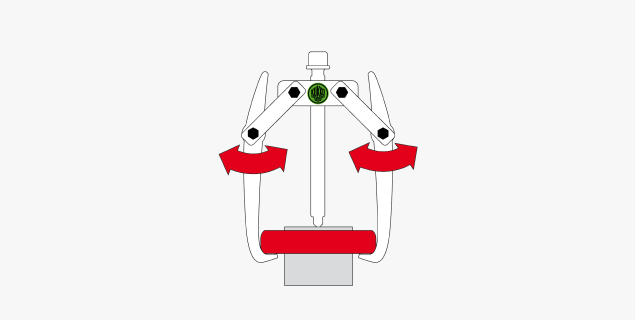

External extraction

A particularly common application is external extraction. Here, the part to be extracted, e.g. a gear wheel, a pulley or a ball bearing, is gripped from the outside. By tightening the spindle, the part to be extracted is released from the shaft.

External extraction tutorial

In this video, our KUKKO testimonial Eric explains the initial situation for external extraction using the example of a ball bearing that sits on a shaft. You will also learn practical tips on how to upgrade a standard extractor with suitable accessories for universal use.

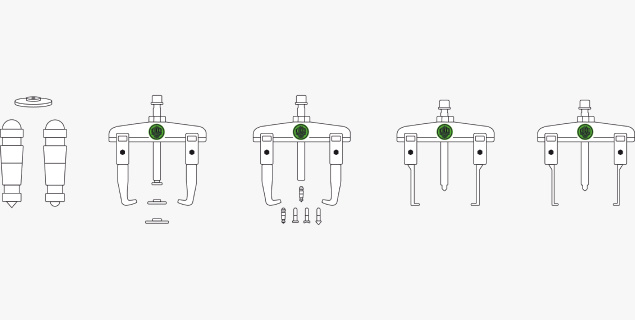

Modular pullers

The modular system is a unique selling point of KUKKO. This results in numerous combination options for the 20 and 30 series with different hook types, thrust pieces, extensions, 2- and 3-arm crossheads and mechanical and hydraulic spindles.

-

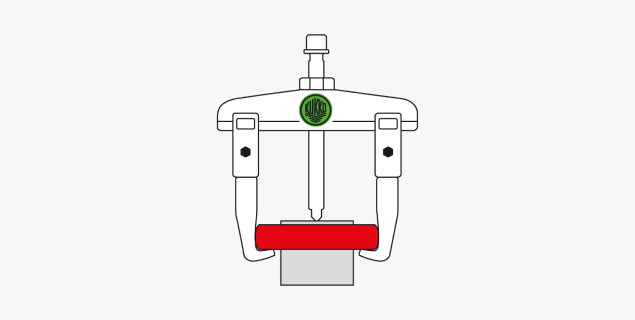

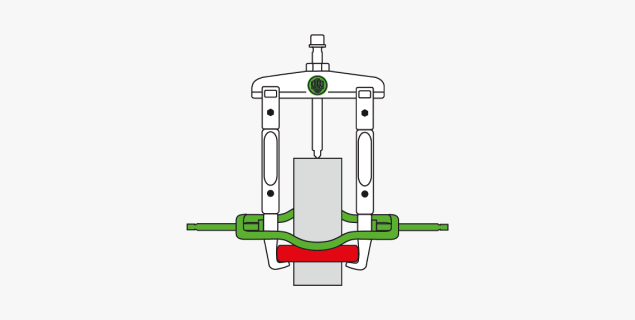

Outside peel

The most common application for extracting is external extracting with sliding, always parallel extractor hooks. The external extractors of series 20, 30 and 11 can be used to grip all components that are located on a shaft and are freely accessible from the outside.

-

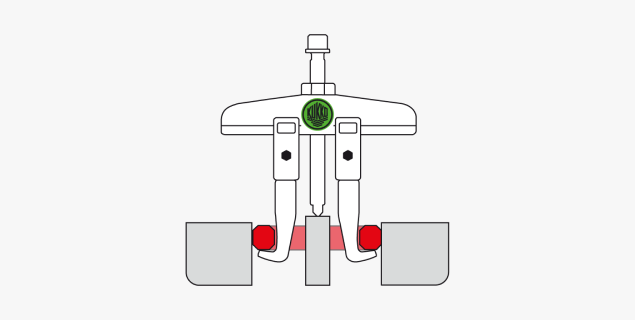

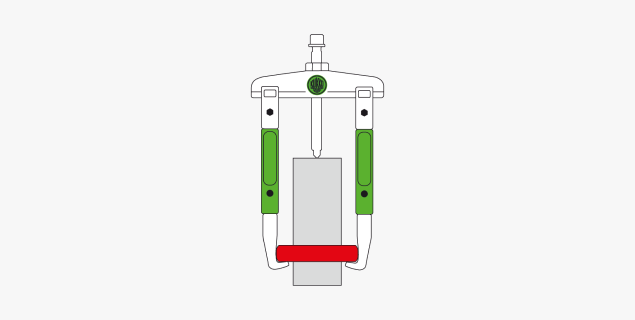

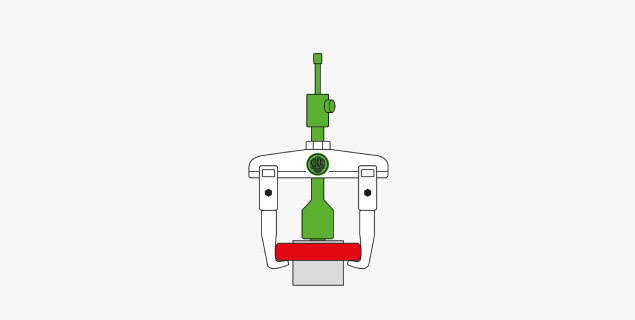

Inside peel off

Thanks to the 2-in-1 function, an external extractor can be converted into an internal extractor by simply reversing the extractor hooks, making it multifunctional.

Special puller

Since no two pullers are alike, the KUKKO range includes special pullers in a wide variety of designs and sizes. Whether pullers with lateral clamping clamp, conical self-clamping or swiveling puller legs - KUKKO has the right solution for every application!

-

The 2-arm bearing extractor "Cobra" series 204 with lateral clamping jaw is used for extracting particularly tight-fitting ball bearings, bearing rings and workpieces. Thanks to the clamp, the contact pressure of the puller legs is increased many times over.

-

The universal pullers with swiveling puller legs (Series 41) ensure maximum freedom of movement for individual adaptation to the respective span width and depth, even in restricted ambient conditions.

Optional extensions

| 2-150-E | Modular extension for trigger hooks (single) |

| MP_219 | Clamp for 2-arm puller |

| MP_9_hydraulic_additional_press | Series 9 Hydraulic auxiliary press |

-

Extensions

For the 20 and 30 series, KUKKO offers modular extensions (compatible with sizes 1 to 20). The extensions can be combined with each other and thus adapted to the required clamping depth.

-

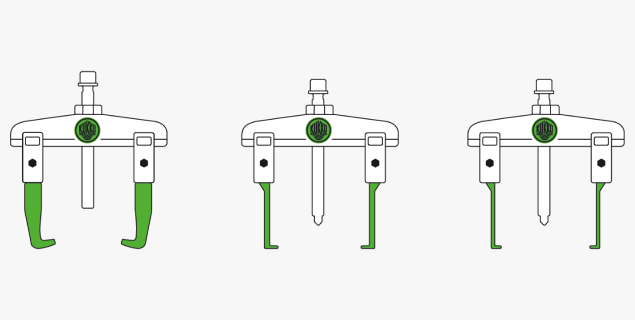

Different types of trigger hooks: Standard - Narrow - Extra Narrow

The narrow trigger hooks ensure that even narrow and poorly accessible spaces can be reached. The extremely slim design of the take-off hooks grips optimally in particularly narrow and poorly accessible places.

-

Spindle tips and exchangeable pressure pieces

Interchangeable pressure pads are the perfect upgrade for KUKKO pressure spindles and guarantee particularly gentle honing on a wide variety of surfaces.

-

Clamp

The clamp for 2-arm pullers is used to support stability during pull-off operations with extensions. For an even better hold, the clamp presses the puller hooks particularly tightly against the part to be pulled off.

-

Grease hydraulic spindle

The hydraulic spindle allows controlled and safe operation from 7-20 t. It uses the full power potential of the extractor, above the possibilities of a mechanical spindle. Moreover, when replacing the mechanical spindle with a hydraulic one, the driving force to be applied is significantly reduced.

-

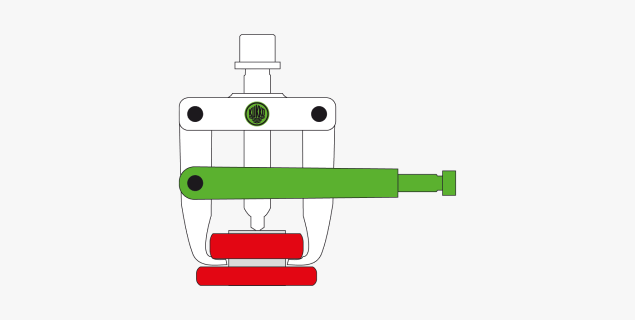

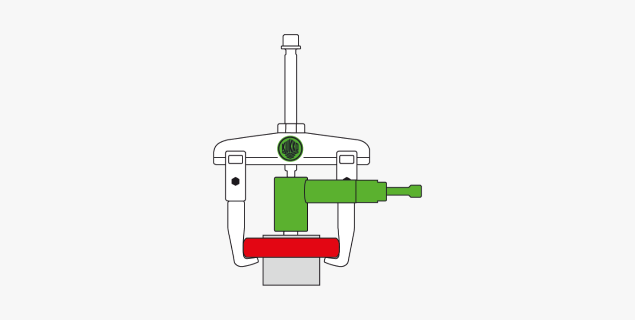

Grease hydraulic auxiliary press

The grease hydraulic auxiliary presses are a good tool to significantly increase the pressure power when removing very tight parts. The hydraulic presses are simply clamped between the spindle and shaft with the mechanical spindle. No modification of the puller is necessary! (For use with mechanical KUKKO pullers from size 3.)

-

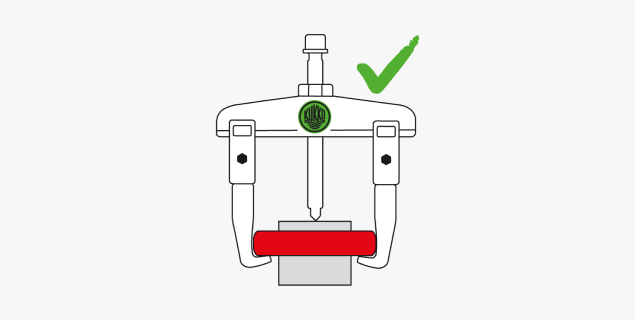

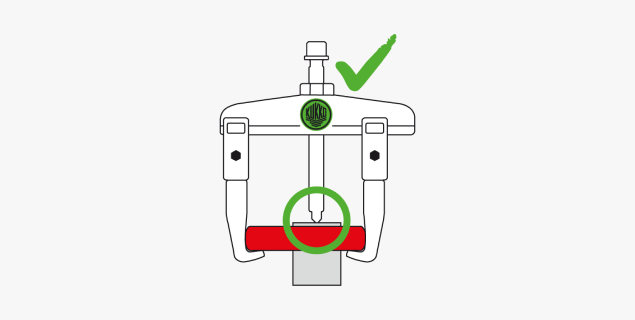

For central shafts, the puller must be applied centrally.

-

If the shaft is not centered, pullers with parallel running pullers can also be pulled off asymmetrically.

-

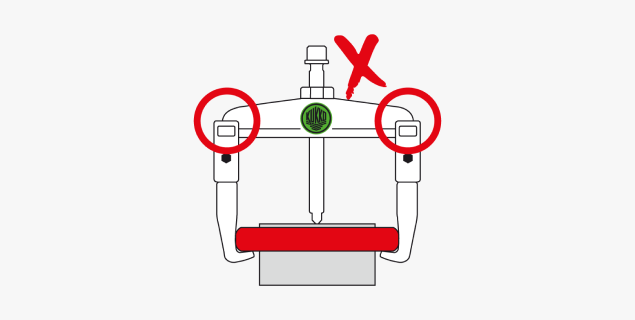

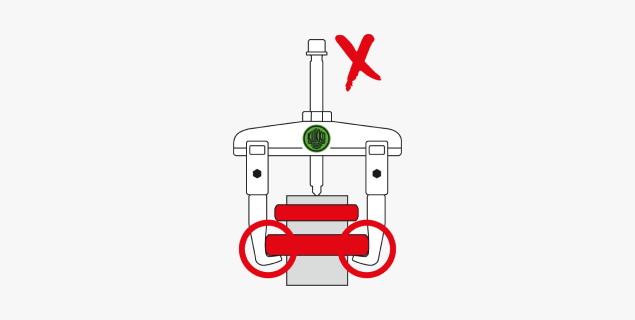

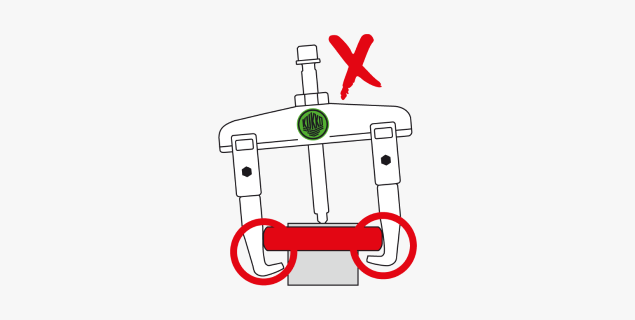

The slide pieces of the trigger hooks must always be completely and firmly seated on the crosshead.

-

Under no circumstances may the trigger hooks protrude above the crosshead.

-

If several parts are to be removed, always remove them step by step. Never pull off several parts at the same time.

-

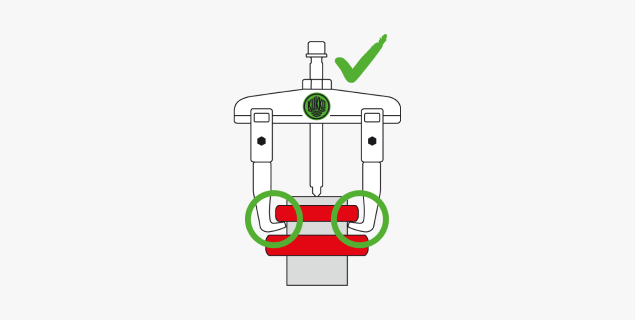

If there is sufficient free space around the part to be pulled off, we recommend a 3-arm puller for optimum load distribution.

-

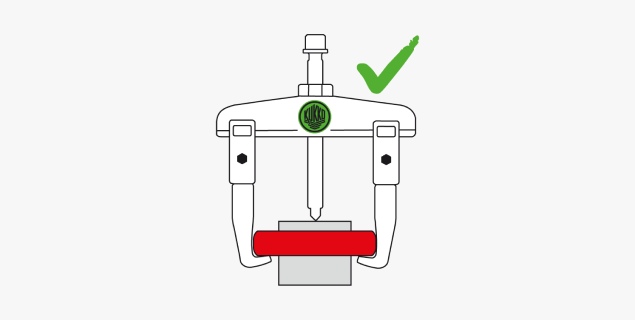

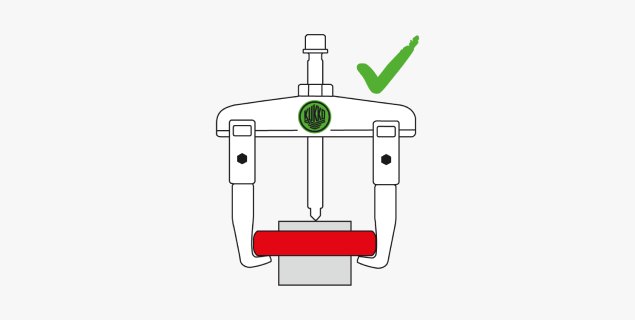

The contact surfaces of the pullers must sit completely and straight under the part to be pulled off. A 2-arm puller is used when there is not enough clearance for the 3-arm version.

-

The trigger hooks do not grip evenly under the part to be pulled off.

Top Products

-

Products 20-5-AV | 2-arm universal puller with adjustable clamping depth

The 2-arm universal puller with adjustable clamping depth is used to pull bearings, gears and discs in all standard sizes for trades, workshops and…

more info...

-

Products Y08-208 | Hydraulic, 3-arm puller with adjustable clamping depth, hydraulic pressure cylinder for pump drive (tractive force up to 10 t) and combi crosshead

The hydraulic, 3-arm puller with adjustable clamping depth, hydraulic pressure cylinder for pump drive and combination crosshead is used to pull…

more info...

-

Products 20-2+B | 2-jaw universal puller with quick adjustable pulling hooks and grease-hydraulic spindle

The 2-jaw universal puller with quick adjustable pulling hooks and grease-hydraulic spindle is used for the particularly safe and user-friendly…

more info...

-

Products 205-3 | Heavy-duty, 2-jaw puller with adjustable reach with oscillating and height-adjustable puller legs

The heavy-duty, 2-jaw puller with adjustable reach with oscillating and height-adjustable puller legs is used for the centric removal of large…

more info...