Puller guide

Separation pull-off

Cutting is suitable for pulling off parts that lie flat, such as ball bearings, roller bearings, inner rings and similar components. The sharp, wedge-shaped cutting edges are pressed behind the part to be extracted and thereby push themselves between the bearing and the seat. For extraction, the pull studs of the extractor series 18 must be screwed into the separator series 15.

Separator-Puller Tutorial

In this video, our KUKKO testimonial Eric explains how to combine the separator and puller to non-destructively disassemble flat-bottomed components.

-

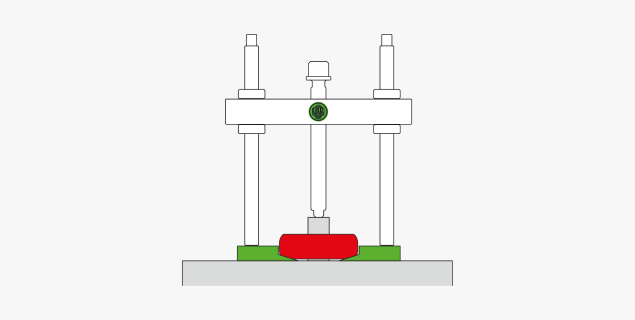

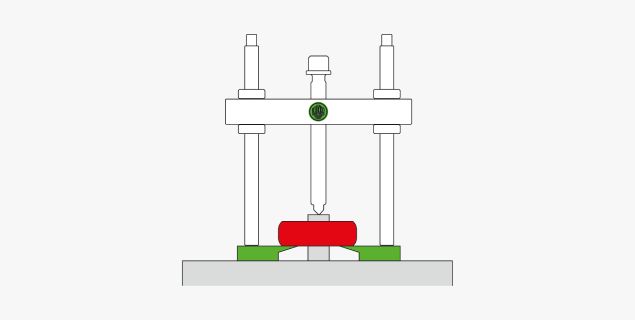

Separation process

During cutting, the sharp, wedge-shaped cutting edges of the cutting device are pressed behind the part to be pulled off. The cutting edges slide between the bearing and the seat. The large contact surfaces protect the part to be extracted and thus enable non-destructive dismantling.

-

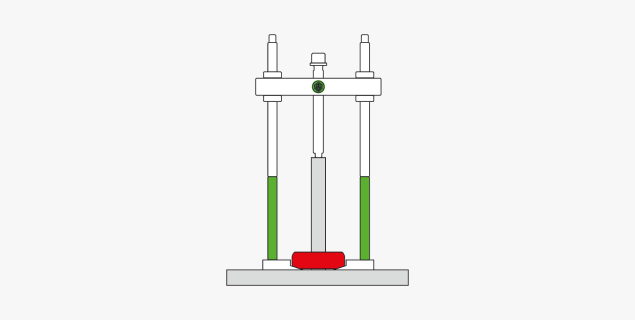

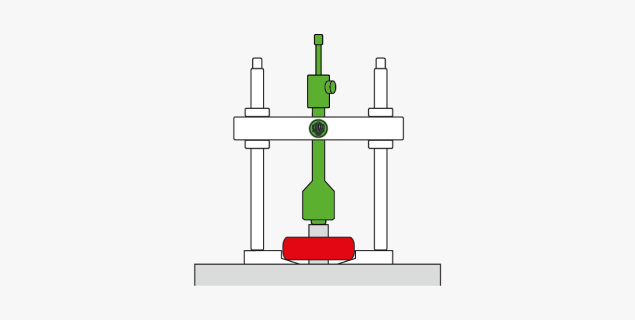

Peeling process

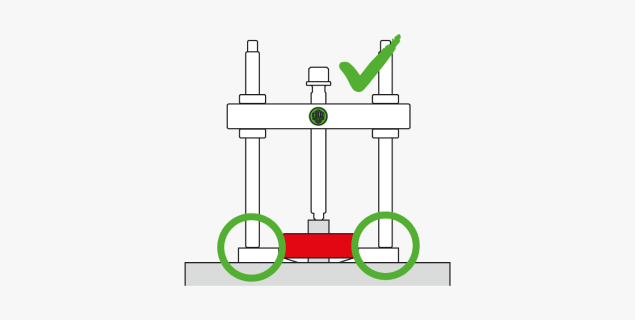

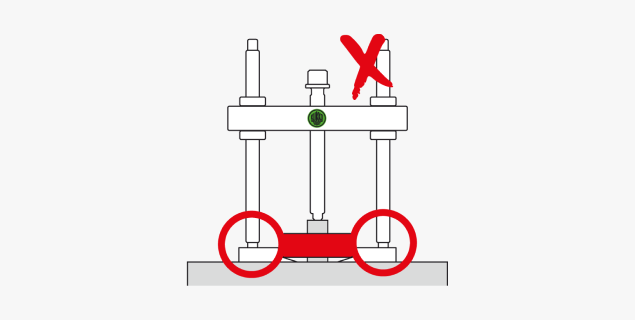

The pulling bolts of the puller are firmly bolted to the separator. This guarantees maximum stability during separation pull-off. When the spindle is tightened, the component is removed non-destructively. If the separating device is screwed into the extractor the other way round, the contact surface is enlarged for even gentler extraction.

Optional extensions

| 2-150-E | Modular extension for trigger hooks (single) |

| MP_219 | Clamp for 2-arm puller |

| MP_9_hydraulic_additional_press | Series 9 Hydraulic auxiliary press |

-

Extensions

The tension bolts of the puller can be extended with extensions series 818. The extensions can be combined with each other as desired and thus adapted to the required clamping depth.

-

Grease hydraulic spindle

The 800 series hydraulic spindle is suitable for pulling off particularly tight bearings, gears and pulleys that cannot be loosened with pure muscle power. A pulling force of 12 t can be achieved.

-

When tightening the separating blades, make sure that they are seated under the part to be extracted as far as they will go before pulling upwards by means of the extractor.

-

-

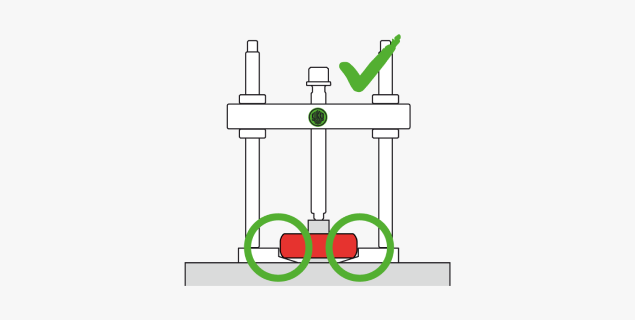

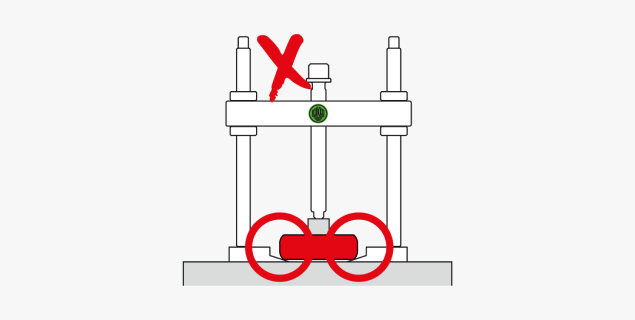

The arms of the extractor must always be screwed into the cut-off knife as far as they will go.

-

Top Products

-

Products Y-315-5 | Separating device for hydraulic PULL/PRESSURE pullers

The Y-15 series separators are used to pull off ball bearings, roller bearings, inner rings and other flush-mounted parts in trade, workshop and…

more info...

-

Products 18-0 | Puller

The Series 18 pullers are used together with the Series 15 and 17 separators to pull off flat or thin-walled parts in trade, industry and workshops…

more info...

-

Products 15-5 | Separating device

The Series 15 separators are used together with the Series 18 pullers for removing ball bearings, roller bearings, inner rings and other flat parts in…

more info...

-

Products 15-2 | Separating device

The Series 15 separators are used together with the Series 18 pullers for removing ball bearings, roller bearings, inner rings and other flat parts in…

more info...